Arc & Gas Welding & Cutting Equipment

OVER 50 YEARS OF SAFFIRE - THE SAFE REVOLUTION

Murex Welding Products Saffire celebrated its 50th anniversary in 2006. Since the introduction of the first Saffire nozzle mix gas welding and cutting system, the brand has become synonymous with absolute safety in all aspects of oxy-fuel welding and cutting.

1956 was the debut year of the Saffire nozzle mix gas welding and cutting system, which fundamentally rewrote the principles and working methods of gas mixing along the lines of safety.

The idea of using a nozzle mixing, high-pressure system was quite well known at the time, but although its safety advantages were recognised, Saffire was the first to put it into practice.

Consequently, Saffire was enormously successful from day one. A market leader from the start, Saffire has grown and changed with improvements since then, but the principle - Safety First - has always been the motivating force behind all developments.

One of the immediate effects Saffire had was the simplifying of the oxy/fuel welding and cutting procedure, and by making the equipment virtually maintenance free, we had also ensured that mixing and handling two of the most reactive gases known was no longer a high-risk operation.

In 1966 the new innovative blowpipe, Saffire 3, won a Design Centre Award.

The original Saffire nozzle mix gas welding and cutting blowpipe has today evolved into Saffire 5. In 2005 it was estimated that there could have been as many as half a million in use throughout the world. Versatility in use and on-going product developments have been instrumental to the success of the Saffire brand. Its application area is immense throughout all sectors of industry and it can be used for heating with acetylene and propane, flame cleaning, rivet cutting, circle cutting, gouging and sheet cutting. It is a system that provides a solution for so many jobs on a day-to-day basis in the workplace.

From the original nozzle mix system, the Saffire gas product range has been dramatically developed to embrace flashback arrestors, regulators and other devices all synonymous with Safety First. Today flashback arrestors are fitted to all oxy-fuel welding/cutting systems and the use of this product is universally recognised as good procedure by Health & Safety Executives and factory inspectors. All Saffire products are now supplied under the quality management system of BS EN ISO 9001.

Saffure was, and still is, a truly earth shaking revolution - and it remains the safest yet. As we've said since 1856,

“Make it Saffire, Keep it Safe.”

CERTIFICATE OF CONFORMITY AND ORIGIN

Under the terms of Consumer Protection Acts 1987 it is an offence to supply consumers goods which fail to comply with the general safety requirements. In order to provide legal protection to our Distributors and end user customers, Murex Welding Products offer a full documentation service which complies with the National Standards and their manufacturing origins. End users can have a peace of mind and assurance that they are dealing with a long established, respected and reliable company.

MUREX EQUIPMENT

MUREX VANTAGE

SINGLE STAGE REGULATORS

MUREX VANTAGE 300 SERIES

1ec SINGLE-STAGE REGULATORS

AVAILABLE IN BOTH (BOTTOM & SIDE ENTRY)

MUREX SAFFIRE 300 SERIES

2+ MULTI-STAGE REGULATORS

AVAILABLE IN BOTH (BOTTOM & SIDE ENTRY)

MUREX E

PRESSURE M600 GP

MULTI-STAGE REGULATOR

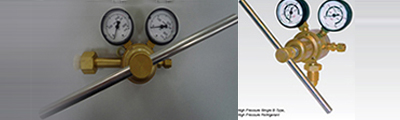

MUREX HIGH

PRESSURE SINGLE STAGE

S-TYPE REGULATORS

SAFFIRE WELDING AND CUTTING BLOWPIPES

MUREX SAFFIRE CUTTING TORCH

SAFFIRE WELDING, CUTTING & PROCESS NOZZLES

MUREX SAFFIRE 5 SUPACET COMBINED OUTFIT

SAFETY DEVICES

(FLASHBACK ARRESTOR)

SAFFIRE HOST CHECK VALVES

PORTABLE STRAIGHT LINE CUTTING MACHINE

ARGON REGULATOR WITH FLOWMETER & CO2 REGULATOR

GL GOLD - LINE WELDING WIRES & CABLES

ARC AIR CARBON GOUGING TORCH